Photography by Tim Nguyen, BFA’06

Written by arch staff

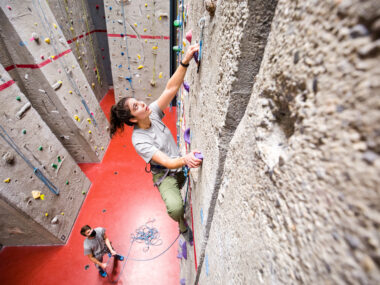

For those not familiar with the world of asphalt research, stepping inside the Bituminous Materials Research Laboratory may feel like being in the workplace of a mad scientist. With various machines and a team of scientists and engineers, the lab is a focal point for product development and materials testing for the asphalt industry in Canada. It’s a mighty feat given the industry’s market size of $4.7 billion in 2022. From highways, airport runways and bridge surfaces, to driveways and parking lots, not to mention the roofs on our houses, we are surrounded by asphalt.

More motor vehicle traffic increasing the load on pavement, large seasonal temperature fluctuations and several other factors mean the cost of road construction and maintenance is going up. The aim of Dr. Martin Jasso, PhD, the Cenovus Energy Endowed Research Chair in Bituminous Materials at University of Calgary, is to develop better flexible pavements through improvements of the engineering properties of asphalt binders.

Our roads rely on asphalt binder as the chief paving material for the construction of flexible pavements. Asphalt is complex. It starts with unrefined petroleum and includes thousands of molecular species with different polarities and molar masses. All that is impacted by use, weather, aging and more. The road running past your home doesn’t seem so simple now, does it?

Here’s a glimpse at some of the machines Jasso and his team use to engineer asphalt that is better for the economy and the environment.